COD (CURING ON DEMAND) – FAST CURING PROCESS

DESCRIPTION

COD is a development of Vulkan AG. Glued and cast components made from a variety of materials are cured and hardened at an accelerated rate through the non-contact introduction of energy with an infrared system which is matched to the materials as a function of time and temperature.

TECHNOLOGY

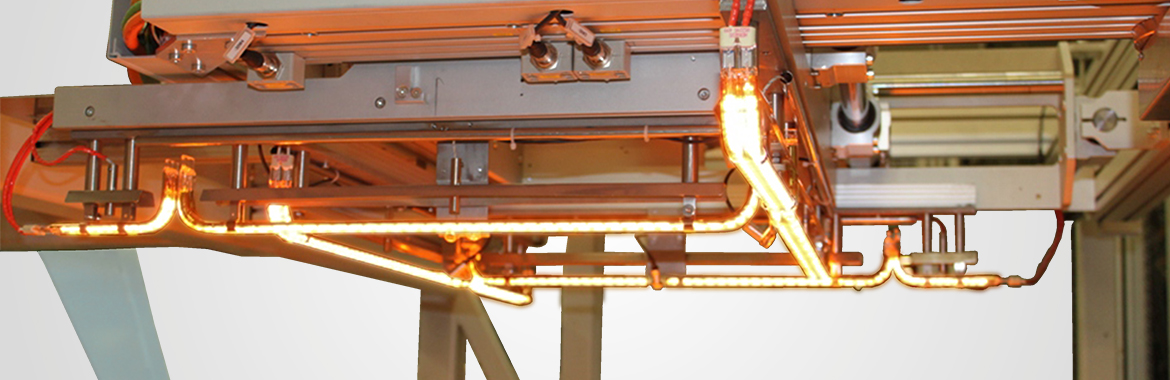

The infrared radiation is able to transfer large quantities of energy within a short time and can be matched precisely to the product and manufacturing steps. The pure quartz glass and low mass enable the process to manage the energy exactly through short response times. This makes the infrared heating technology economical and precise. Depending on the temperature, the radiator emits different quantities of radiation in various wave bands. If the wavelength of the infrared radiation is correctly selected according to the product, this has a significant impact on the heating process. Short-wave radiation penetrates deep into solid materials and ensures uniform warming. Temperature measurement methods (sensors) which are specifically matched to the process and have correspondingly fast control loops, as well as the ultra-fast communication of the energy released in combination with the aforementioned properties of the infrared radiation accelerate the introduction of heat into the product once again. Reflectors attached in a targeted manner bundle the energy precisely to the desired unit while the system and surroundings remain cool.

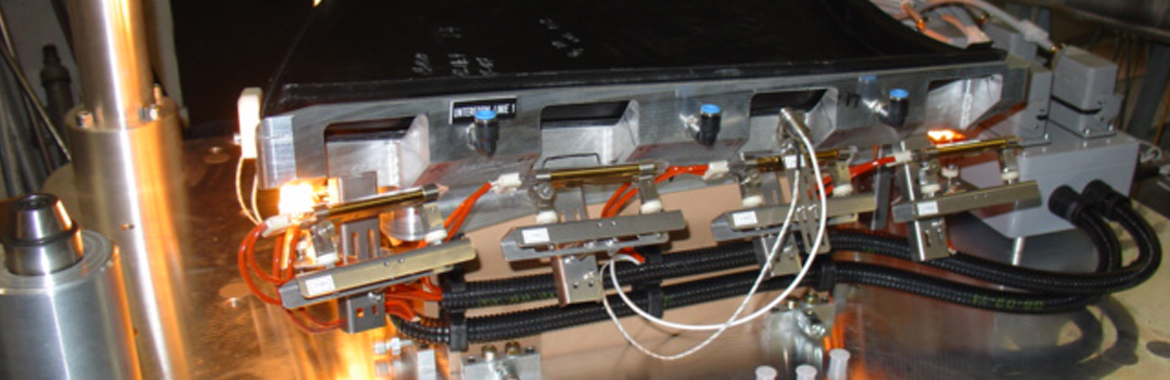

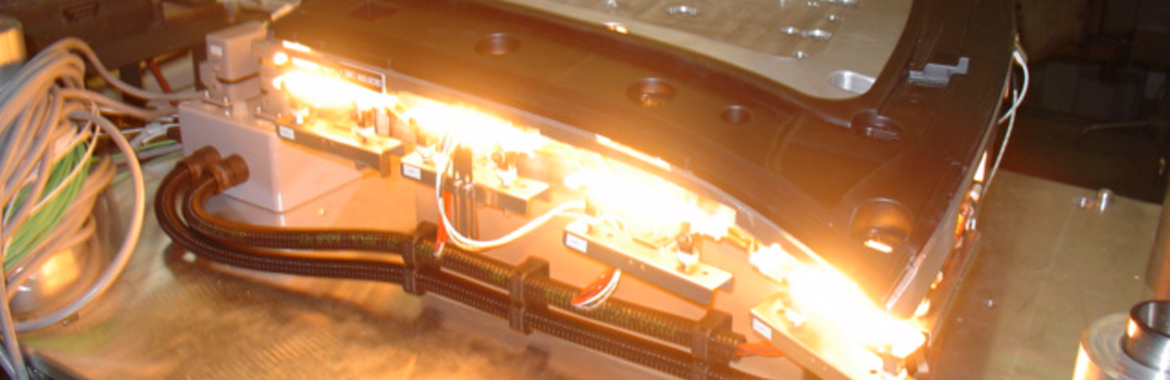

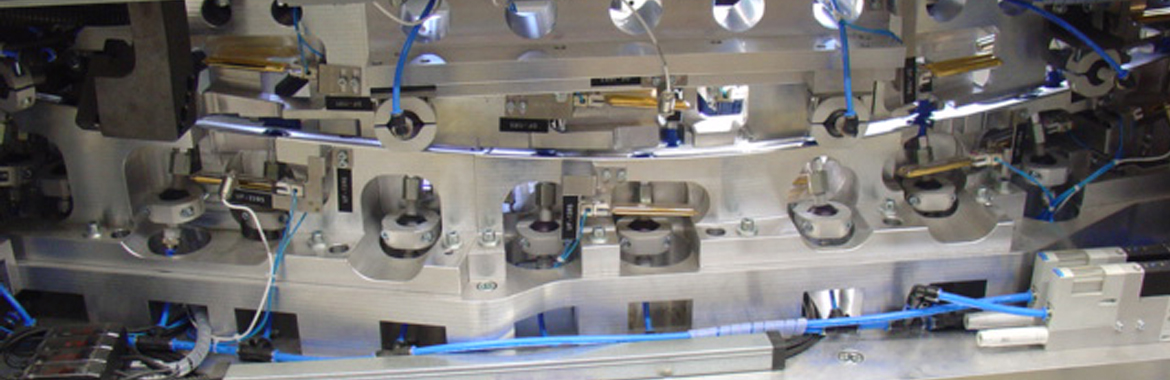

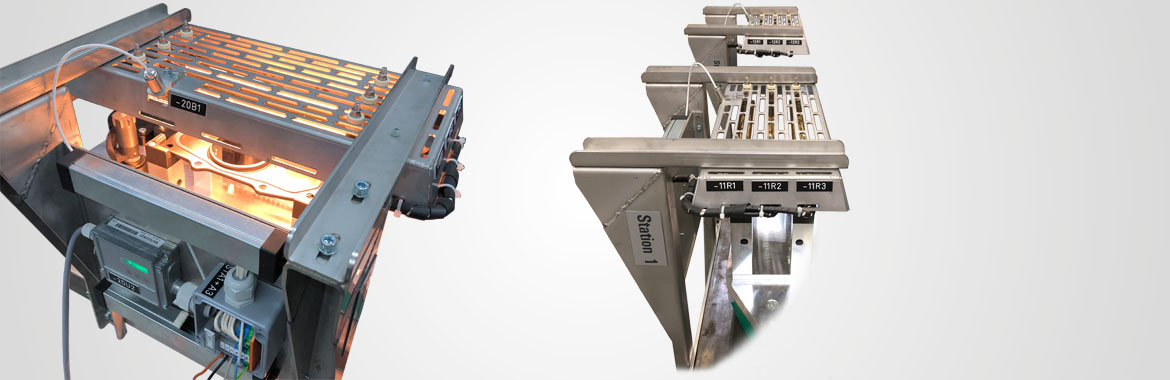

INTEGRATION INTO TOOLS

In the case of simple clamping tools, the clamping frame can be moved directly under the COD, with the desired effect being achieved very easily if the clamping frame is designed accordingly. With complex tools, COD units can be attached to the circumference of the parting surface between the upper and lower section of the tool. The results are improved by equipping individual tool elements with COD units circumferentially on the bonding line to be fixed in place. Cast components are moved directly under the COD unit. The double-sided irradiation of bonded surfaces also strengthens the effect.

COD TEMPERATURE CONTROL

Temperatures are measured without contact by sensors. Laser pointers for the visualisation of the measurement points on the work pieces can be switched separately. The length of the irradiation process is limited by the pre-determined time unit. All of the parameters defining the process are visualised and operated by means of a touch panel. For the targeted tempering process in terms of accuracy, temperature distribution and energy penetration depth, the non-contact COD control system developed specifically for these applications is used.

COD has the undisputed advantage of precisely coordinating the heat output of the IR emitter, the wavelength and surface temperature, as well as the penetration depth of the emitted radiation into the product. The fine, rapid and non-contact introduction of energy into the component protects the adhesive. It has been shown that it is even possible to irradiate components that have already been surface-coated (irrespective of the colour, light/dark) in such a way that in an extremely short time the bonding of the surfaces is accelerated by the heat energy that is introduced without destroying the coated surface.

ADVANTAGES OF COD

The high quality is shown by the strength and shape-retention of the components, as the energy is only partially introduced into the area being bonded, so that the distortion of the bonded parts is kept to a very low level. After treatment with the COD procedure, the bonding process is so far advanced that when the halves of the tool are opened, the bonded component displays much more than simple "handling strength" and that as a result it retains its shape.

The investment costs are greatly reduced because fewer clamping tools are required. As a result of the accelerated curing process, there is no longer any need to put the components into intermediate storage for the remainder of the curing process after they have been taken out of the clamping tools. Cast components are cured within a very short time with a very low energy requirement and without space-consuming curing furnaces.